Page 16

Sword forging process illustrated part 2

|

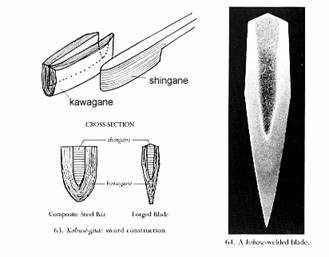

The finished blade is shown here after being polished to reveal the true hamon. |

Example of a Japanese forge |

The swordsmith used fire, water, anvil and hammer to shape the world’s best swords. After forging the blade, the sword polisher did his work to prepare the blade for the “furniture” that surrounded it

Sword makers were revered as artists and holy men, and a sword maker’s shop was seen as a shrine, where holy work was done. A typical sign outside such a shop might read: “Souls polished here.”

This picture and diagram clearly illustrate the difference between the hardened cutting edge of the blade and the softer back edge of the blade. This being the secret that allows the Japanese katana to be used with great force with out breaking.

|